Transparent resource management

With the production planning and control module, FactWork offers the right solution of every company size and complexity, for efficient planning, control and monitoring of the resources. So that you always know who does what and when.

Simplest capacity planning

The aim of production planning is to dispatch production orders with consideration to the production duration and completion deadline. Simple capacity planning facilitates the best possible capacity utilization of the machine outfit through determination of the optimum execution sequence. In the area of cost-oriented detailed planning and optimization, the FactWork scope of operation is enlarged through a DUALIS GmbH module.

Consideration of all pertinent parameters

Machine capacities and employees, as well as their qualifications are also taken into consideration, alongside the availability of the required material. Detailed planning from sales can also be applied, for the determination of delivery deadlines.

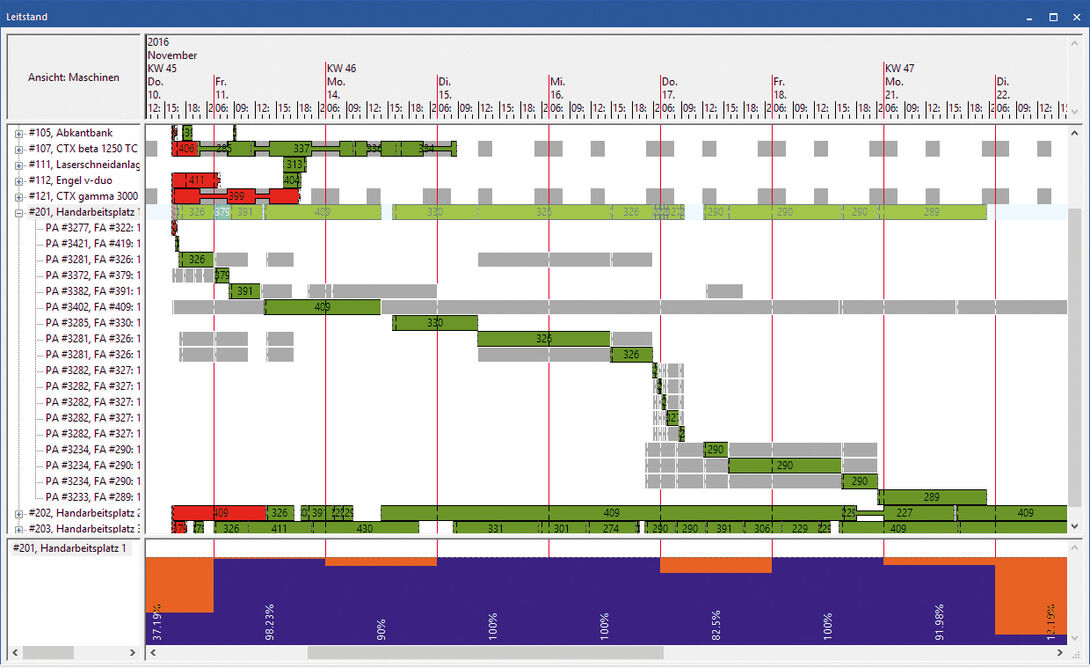

Visualisation of the current situation in real time

To facilitate optimum production control, the situation in production is visualised via the control station, which is updated in real time through BDE postings. This enables the early signalling of delays, bottlenecks and leeways, which in turn allows the short-term initiation of counteractions. Pending process steps are visualised for every machine via an order backlog screen. Also integrated are the control and monitoring of external production or finishing.

Reliable material tracking in production

FactWork optionally also offers material tracking in production per load carrier with assignment of the material to the operation.

Advantages and features at a glance

- Efficient planning, control and monitoring of the resources.

- Ideal solution for every company size and complexity.

- Simplest capacity planning.

- Determination of the best possible capacity utilization of the machine outfit.

- Cost-oriented detailed planning.

- Consideration of all machine capacities, employees, their qualifications and the required material.

- Visualisation of the current situation in real time.

- Early signalling of delays, bottlenecks and leeways.

- Control and monitoring of external production or

- finishing. Reliable material tracking in production.

Download (German language)

You will find further information in our product brochure.

FactWork brochure (German language)

These software products may also be of interest to you

Condition Monitoring with fe.screen-analytics